What sets engineering bricks apart from other bricks is their design – they have been manufactured to have an extremely high compressive strength, durability, and low water absorption. Our engineering bricks for sale are wirecut with a smooth plain surface and are split into 2 different categories: Class A and Class B.

Class A bricks have a compressive strength of 125N/mm2 with a water absorption rate of less than 4.5%. Class B bricks have a compressive strength of 75N/mm2 with a water absorption rate of less than 7% - the only difference is essentially how touch they are.

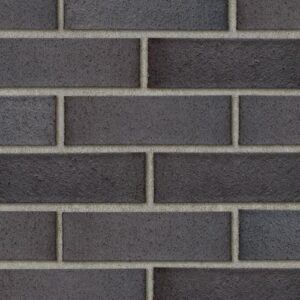

You will find both red engineering bricks and blue engineering bricks in Class A and Class B, and this normally dictates which class the engineering brick is categorised as.

Red engineering bricks are usually a Class B brick, and you will find that they have a smooth finish with perforated holes in the top and the bottom to allow them to bond more securely.

Blue engineering bricks are usually a Class A brick and are much stronger than the Class A bricks. Blue engineering bricks are fired at extremely high temperatures in a low oxygen environment to give them their blue finish and add extra strength. You can find a wide range of dark blue engineering bricks, but they are rarely used for their colour.

What are smooth engineering bricks used for?

Our engineering bricks for sale have a much more important use than simply making your building look nice – they are needed for strength and durability. Typically, you would find 75mm engineering bricks in the footings of the building, with two more courses of smooth engineering bricks above ground to secure the foundations. If you look at a lot of buildings, you will see that there are usually 2 different colours of bricks along the bottom, for example dark blue engineering bricks and red engineering bricks. 73mm solid red engineering bricks are also essential in dampproof courses to prevent rising damp in buildings. They are ideal for this job as they have a low water absorption rate, and you will often find them in bridges, canals, and tunnels.

Features and benefits

- Functional use for strength and low water porosity

- Used above and below damp-proof courses

- Reusable and eco-friendly manufacturing process

- Suitable for below ground applications

- Standardisation and manufacturing process provides dimensional accuracy

- Frost and acid resistant

If you are looking for something strong, durable, and water resistant, you need to be looking to buy blue engineering bricks. We have a wide range of red, blue, and

reclaimed engineering bricks for sale at prices to suit every budget and project.

Natural Variation Information

If you are looking to buy blue engineering bricks, it is important to note that all our bricks are made from naturally occurring materials. Therefore, the colour and texture will differ slightly for each brick fur to the various locations in which they have been sourced from.

FAQs

What are engineering bricks?

Engineering bricks are smooth, perforated, wirecut bricks that are used where strength and durability are essential. They are known for their physical properties rather than how they look, and they have high compressive strength with a low water absorption rate.

What are red engineering bricks? What are red bricks used for?

Red engineering bricks are usually used for applications where strength and low water absorption is essential. They are generally a class B brick, and they are used for dampproof courses, foundations, tunnels, bridges and canals.

What is a class A engineering bricks?

A class A engineering brick is a smooth, perforated, wirecut brick that is used where strength and durability are essential. They are known for their physical properties rather than how they look, and it has a compressive strength greater than 125N/mm2 and water absorption of less than 4.5%.

What is a class B engineering bricks?

A class B engineering brick is a smooth, perforated, wirecut brick that is used where strength and durability are essential. They are known for their physical properties rather than how they look, and it has a compressive strength greater than 75N/mm2 and water absorption of less than 7%.

Why are bricks different colours?

Bricks are different colours due to the manufacturing process they go through to change their properties. Red bricks are usually a class A, and this is the standard colour of brick with no additional work. Blue bricks are usually a class B and are fired at higher temperatures with low oxygen to make them even stronger.

How are blue engineering bricks made?

Blue engineering bricks are made using red clay, and then they are fired at a high temperature in a low oxygen environment to give a deep blue colour. This makes them stronger with a lower water absorption rate.

How are red engineering bricks made?

Red engineering bricks are made from high-quality clay and heated at a high temperature, but lower than that used to make blue bricks. This high temperature gives them their useful properties, including a high compressive strength and low water absorption rate.

Are engineering bricks waterproof?

Yes, engineering bricks are waterproof thanks to their low water porosity. This means that they are resistant to water and to frost, and subsequently commonly used for damp proof courses and for bridges, canals, and tunnels.

What is the strongest type of brick?

Engineering bricks have been specifically manufactured to be the strongest type of brick, much stronger than facing bricks, which are chosen for how they look. Engineering bricks have an extremely high compressive strength, making them perfect for building foundations.

Do engineering bricks stop damping?

Unlike the wide range of textures and the high levels of porosity found in normal bricks, engineering bricks have a low water absorption rate which means that they will help to reduce dampness and keep the building dry.

They are often used above and below dampproof courses.

Are engineering bricks frost resistant?

Yes, engineering bricks are both resistant to frost and waterproof thanks to their low water porosity. This means that they are resistant to water and to frost, and subsequently commonly used for damp proof courses and for bridges, canals, and tunnels.

Can you paint bricks?

Yes, you can paint bricks if you want to freshen them up or add a decorative feature. If you are painting the bare surface, then it is important that you apply a primer before you paint. The primer will act like a glue and will allow the paint to stick secure to the surface of the brick.

Which bricks are good for the foundation?

In order to have a secure foundation, you need to choose a strong brick. Engineering bricks have a high compressive strength that are able to bear the load of walls with reinforcement from other materials.

Why are engineering bricks blue?

Blue engineering bricks are normal clay bricks that have been turned blue as a result of being heated at extremely high temperatures in a low oxygen environment. This means that they are not only strong and durable, but their surface is impervious and water resistant.

What are the sizes of an engineering brick?

Engineering bricks are generally 215 x 102.5 x 65mm (L x W x H) and are characterised as a very dense brick with a high crushing strength. They offer damp resistance and frost resistance thanks to their low water porosity and are specifically made to improve the structural performance of a building.

How heavy is an engineering brick?

A standard engineering brick that measures 215 x 102.5 x 65mm (L x W x H) will weigh approximately 3.01 kg

Why do engineering bricks have holes?

Engineering bricks are manufactured to make the most of their strength and not for their aesthetic value, and the holes in the bricks serve the main purpose of allowing the bricks to be locked together firmly by allowing mortar to seep through.

What is the difference between an engineering brick and facing bricks?

The main difference is that engineering bricks have a higher compressive strength, whereas facing bricks focus more on the aesthetic and how they make the building look. Engineering bricks do not have any requirement for a certain colour or texture, and they are traditionally used in civil engineering work.

How can you tell the quality of bricks?

Bricks will undergo a series of tests to ensure that they are suitable for the job in hand before they can be sold, but there are some things that you can look out for to see if you are choosing quality bricks including uniformity of colour (they should all be roughly the same colour), how sharp the right angle corners are, and if they are uniform in texture.

How long will an engineering brick last?

Bricks that are made from clay are durable, sustainable, and reusable and you can expect a single brick to last between 150 – 500 years. You need minimal maintenance to keep this average life span, and with regular care and attention such as mortar replacing your bricks will stand the test of time.

How much does an engineering brick cost?

Engineering bricks can cost you as little as 70p per brick, and you can buy packs of bricks in a variety of different sizes to suit all construction needs and requirements.